E-Waste

Read how a Kiwi, an Indian and a Finnish startup are tackling the e-waste crisis

👋 Hi there,

If this is your first time here, welcome!🙂 Every week, I cover 3 startups across the world that wouldn’t have been founded if the founders said ‘🤷🏽♂️ Not My Problem’.

If you haven’t subscribed yet, you may want to consider doing that. Every Friday, these posts will directly land in your inbox.📨

Some housekeeping: To make sure that ‘🤷🏽♂️ Not My Problem’ lands in your inbox every Friday, please move it to your primary inbox if you use Gmail, add it to your VIP list if you use Apple Mail, add it to your favourites if you use Outlook or some combination of the above if you use anything else.

Improper e-waste recycling is a major emerging hazard, silently affecting our health and that of future generations- Maria Neira, WHO

Electronic goods like phones and laptops and electrical ones like refrigerators, microwaves and kettles have become an integral part of our lives. A lot of them contain toxic chemicals, which if not disposed of properly, damages the environment and human health.

Also, e-waste contains precious metals like copper, iron, gold, silver and platinum. $10bn of these precious metals are dumped each year in e-waste.

The level of recycling is not keeping up with the amount of e-waste generated, which is rising three times faster than the world’s population.

Let’s see how these three startups- Mint Innovation, Binbag and Swappie are building innovative solutions to tackle this ⬇️

🥼Recovering gold from the urban mine

We are sitting on a gold mine…The e-waste contains many valuable raw materials like gold. In fact, the concentration of gold in e-waste is ~100 times more than its concentration in gold ores dug out of Earth. As a vast majority of e-waste goes unrecycled, precious metals worth billions are lost due to that. Moreover, the current model to recycle e-waste includes shipping large quantities of it to centralized locations, where these metals are extracted using traditional methods like pyrometallurgy (burning away plastics to reveal metals, which are then melted using heat)- an energy-intensive and hazardous method.

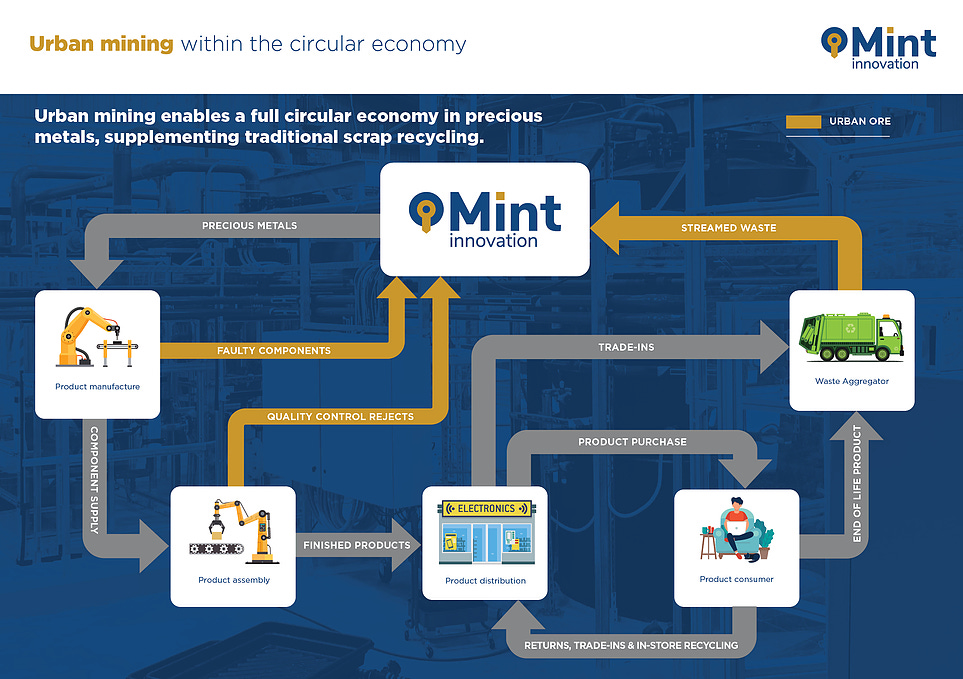

Turning trash into treasure…New Zealand based urban mining company Mint Innovation has developed a novel biotechnological solution that uses inexpensive chemicals and microbes to extract precious metals from e-waste. The e-waste is turned into a powder and the base metals like copper, iron and tin are removed first, leaving behind the precious metals. Acids and oxidants are then added to dissolve the metals into a liquid solution, where Mint’s special microbes are able to find gold and accumulate it on their surface. These gold coated microbes are then filtered out and the metal is separated from them.

Creating a circular economy…Based on its innovative solution, Mint's mission is to set up biorefineries in all major cities across the world. These refineries will take the e-waste from the local communities, extract the precious metals from it and then sell them back to local businesses such as jewellers and manufacturers. These biorefineries are less energy-intensive as compared to the traditional methods. Also, their local presence brings down the shipping cost and time to recycle for e-waste aggregators- creating a low-impact, low-waste, low-carbon alternative to traditional methods.

♻️Creating a distributed recycling model for e-waste

Informal recycling practices… In most of the developed nations, formal recycling practices for e-waste are taken seriously. It’s a standard 3 step process- collecting e-waste, transporting it to a central location and processing it. Though it is highly effective, it takes up significant financial resources which developing nations can’t afford. As a result, informal recycling practices have emerged in these countries. Using primitive methods, individuals(without any safety equipment) extract precious metals from e-waste and the remaining waste is burned, buried or discharged in the waterways, leading to environmental contamination.

A decentralized model… India alone produces around 2 million tons of e-waste annually, ~90% of which ends up in the informal sector. While regulations exist for e-waste disposal for bulk manufacturers, small retailers and consumers still don’t know their role. Bengaluru based Binbag is creating a decentralized model to treat e-waste produced by Small & Medium Enterprises(SMEs). As opposed to having 1 centralized recycling unit, they have 3 recycling units that are strategically situated (closer to the market- lower logistics cost & carbon footprint) across different parts of the country. Binbag owns the entire supply chain, from collecting the e-waste to recycling it in their own facilities.

The growth trajectory… Founder and CEO Achitra Borgohain believes that the success of a circular supply chain model depends on three factors- Awareness, Access and Assets. In the world of e-waste recycling, it translates to creating awareness amongst SMEs and individuals regarding e-waste disposal, lowering transportation costs for e-waste collectors who send the waste to recycling units(access) and developing an optimum capacity of recycling units(assets). To cater to customers in tier 2 & 3 cities, Achitra wants to work with smaller distributed recycling units that are already functional in these cities.

📱An end to end online marketplace for refurbished iPhones

Do we need a new phone?… Most people update their phones every ~21 months. The older phones usually end up in a drawer in the house and are eventually disposed of with other e-waste. If they end up in a landfill, precious metals are lost and they contaminate the environment. Moreover, the production of new smartphones takes up additional resources and emits greenhouse gases. Research shows that extending a mobile phone’s life from 1.8 to 4.5 years can halve the carbon footprint of the phone’s life cycle.

A cheaper, environment-friendly option…The smartphone market in Europe is over €100 billion. The used/refurbished market makes up only 10% of it. Finnish startup Swappie is on a mission to change that %age. It collects used iPhones from individuals and private organizations, repairs them in its own factory and resells them directly to consumers with a 12-month warranty (controlling the entire value chain). If the collected phones cannot be reused, they are used for spare parts and are then taken to e-waste disposal points.

Win-Win-Win… Trust plays a key role when it comes to purchasing refurbished goods. Swappie is building that by controlling the entire value chain, providing warranty and free return options to the end-user and ensuring that these refurbished phones work as well as new ones. The sellers earn by selling their old phones to Swappie and the customers get a phone at a discounted rate while saving the environment. The company has recently expanded its operations to ~26 countries in Europe.

🔍Quiz Time

The e-waste produced annually is worth over $62.5 billion, more than the GDP of most countries. -UN report, 2019

In order to act, we need to be aware. Want to test your awareness about the e-waste crisis? Answer these 5 quick questions.

⏮️From the last edition

🔖 In the last edition, I wrote about the water crisis. If you didn’t get a chance to read it, here it is.

💻 Prefer to watch something instead? Here’s a 20-minute explainer of the world’s water crisis.

😯 Are you a fan of bottled water? Troubled Water by Netflix might make you rethink.