Got a junk drawer filled with tangled chargers?

With this new regulation, things might change

Last week, the European Union proposed new regulation.

This would require all the small electronics to have USB-C standard charger within 2 years.

We are talking about phones, tablets, speakers, cameras.

Critics(read Apple) are saying that this will hamper innovation.

As an Apple user, I don’t agree!

I sat down and counted at least 7 different types of chargers at my place. And all of them could just have been 1 charger.

The impact of this (if implemented) might be not that significant. But it would at least push the brands to start thinking about standardization.

What do you think?

For this week, let’s see how these 3 startups are solving the problem of e-waste across the world⬇️

Less than 5% of batteries are recovered…As the electric cars grow, the Lithium-ion batteries grow. But as these batteries come towards their end of life, there’s no formal waste management system for them. Individual metals like copper, nickel, and cobalt are extracted from these batteries using dirty and energy-intensive methods like hydrometallurgy (extracting metals using aqueous solutions) and pyrometallurgy (extracting metals using high temperatures), which are harmful to the environment.

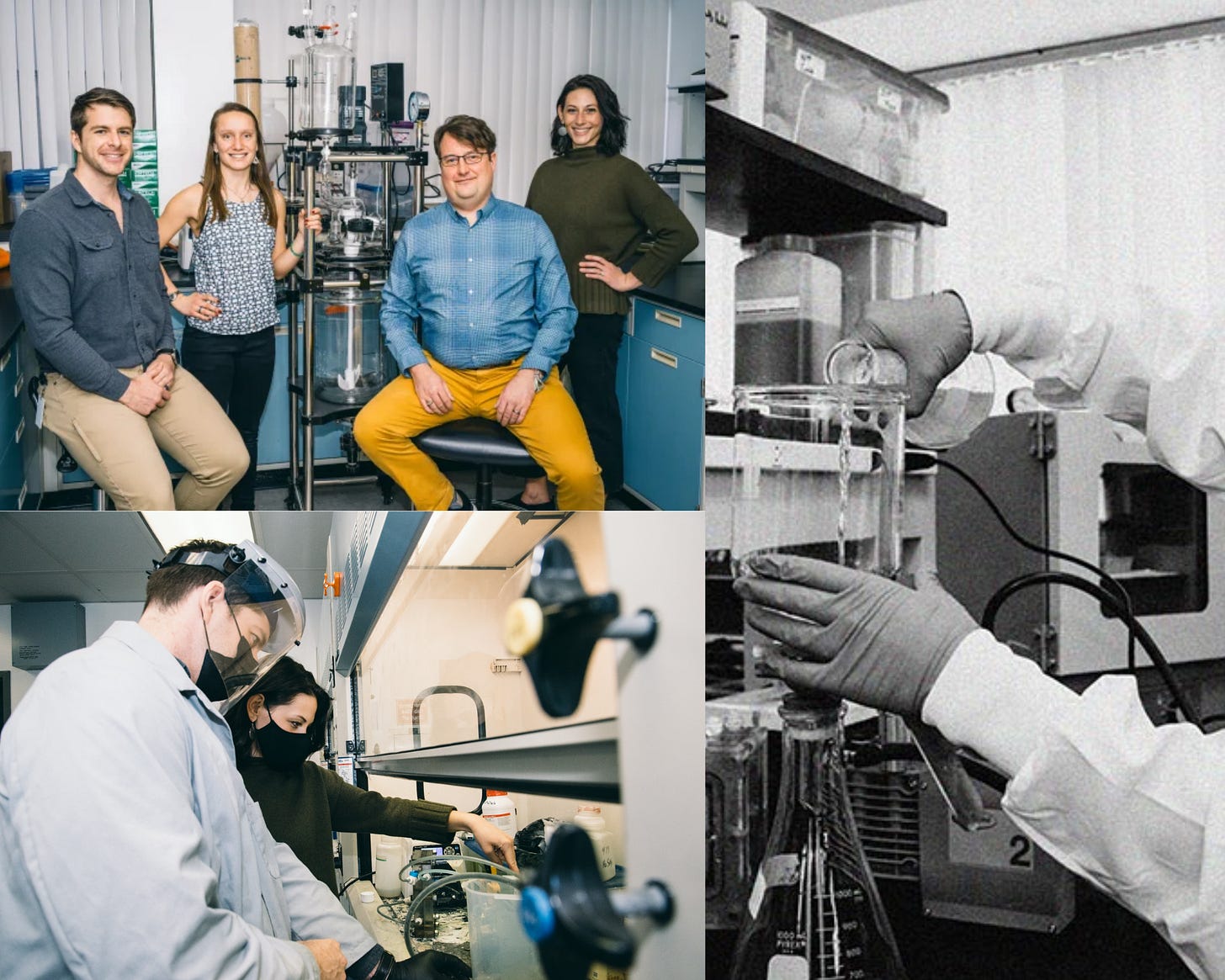

A cleaner alternative…A metal processing and recycling technology company, Nth Cycle is working with recyclers and miners to extract these precious metals while minimizing the environmental damage. These critical minerals are then reused in batteries and wind turbines.

Black mass- a powdery waste substance that’s generated from the battery recycling process is fed into the Nth Cycle’s system.

Using a customizable and clean electro-extraction technology, valuable minerals like nickel, cobalt and manganese are extracted from this mass.

These minerals can then be reused in new lithium-ion battery production.

Not just from batteries…but a lot of precious metals are lost during the mining process too. A lot of waste is generated in the mining process. Nth Cycle’s technology can also help miners unlock these untapped minerals by collecting up to 30% of metals that were not extracted in the original mining process.

50 million tonnes…That’s the amount of e-waste generated by consumer electronics every year. Millions of mobile phones discarded by us simply end up in landfills. Each of them contain precious metals that are wasted as well. Our throwaway culture is leading to harmful emissions, toxic chemicals in the soil and depleting mineral resources from the planet.

Give them another chance…UK based Reboxed is making a positive impact on the society and the environment by following a circular model- rebox, rehome, repeat. They are providing a new home to old phones. The brand is on a mission to rehome 100 million devices by 2030. Consumers and businesses can sell, swap or shop their old gadgets with Reboxed.

Reboxed performs a 70 point TechCheck® to ensure the old phones are as good as new.

They pack them in a sustainable case and sell them with a 15 month warranty at 40% cheaper than the new phones.

They even buy the second hand phones back from you.

Standardization to the rescue…Using their TechCheck® app, customers can get an accurate price for their phone in minutes. They can then sell instantly by booking a collection from home. Reboxed also plants 10 trees per device sold to offset the carbon emissions of the phone for its lifetime. The startup wants their TechCheck® app to be an industry-wide norm for second hand phones.

It comes at a cost…India’s burgeoning, tech-savvy economy has created the massive problem of e-waste in the country. Only 2% of the country’s electronics are being recycled currently. And that too happens in a way where little thought is given to social and environmental aspects (using acid baths to extract precious metals from e-waste). In hundreds of small undocumented shops, people dismantle junked desktops, laptops, monitors, smart phones, and all sorts of old gadgets by hand.

From pickup to responsible recycling…To tackle the problem of e-waste in the country, Karo Sambhav is building a country wide cohesive e-waste movement. They are bringing hundreds of companies, government institutions, informal sector aggregators and repair shops on a single platform to keep the e-waste out of the landfills. Using technology, they are weaving transparency in the entire ecosystem.

Everything that is collected by e-waste aggregators is documented and barcoded by the team before it is sent to the recycling facility.

This information is hosted on the Microsoft cloud and at every stage of the transaction, the bill is tallied with the physical e-waste.

Even the logistics trucks that carry the e-waste from the aggregators to recyclers are GPS-enabled and can be tracked.

Responsible recycling…All the collected e-waste is dismantled and recycled in an environmentally sound way. They are present in 28 states and 3 union territories in the country. Individuals can also request the Karo Sambhav team to collect their e-waste, irrespective of the quantity or weight. They also have the option to track its recycling process.

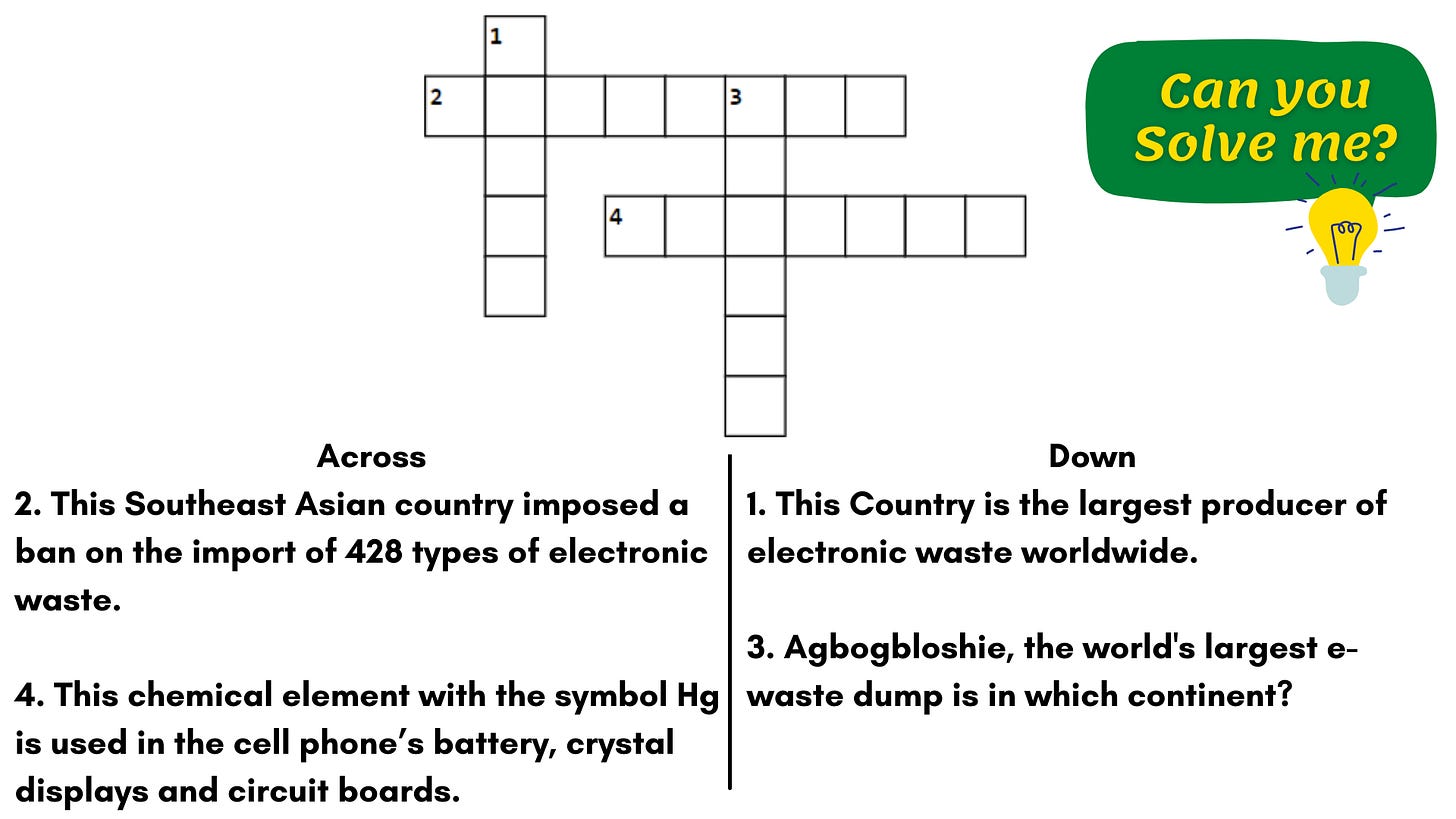

🔍Ready for this week’s crossword challenge?

You can solve it here

If you liked this edition, please do share it. That would mean a lot😊

📢 Shoutout to Paridhi who helped me write this edition.

Hit that 💚 if you liked today’s edition.

Are you following us on Instagram?

Thanks and see you next week😄