The massive CO2 emitter you may not have heard of

It's responsible for 8% of the greenhouse gas emissions

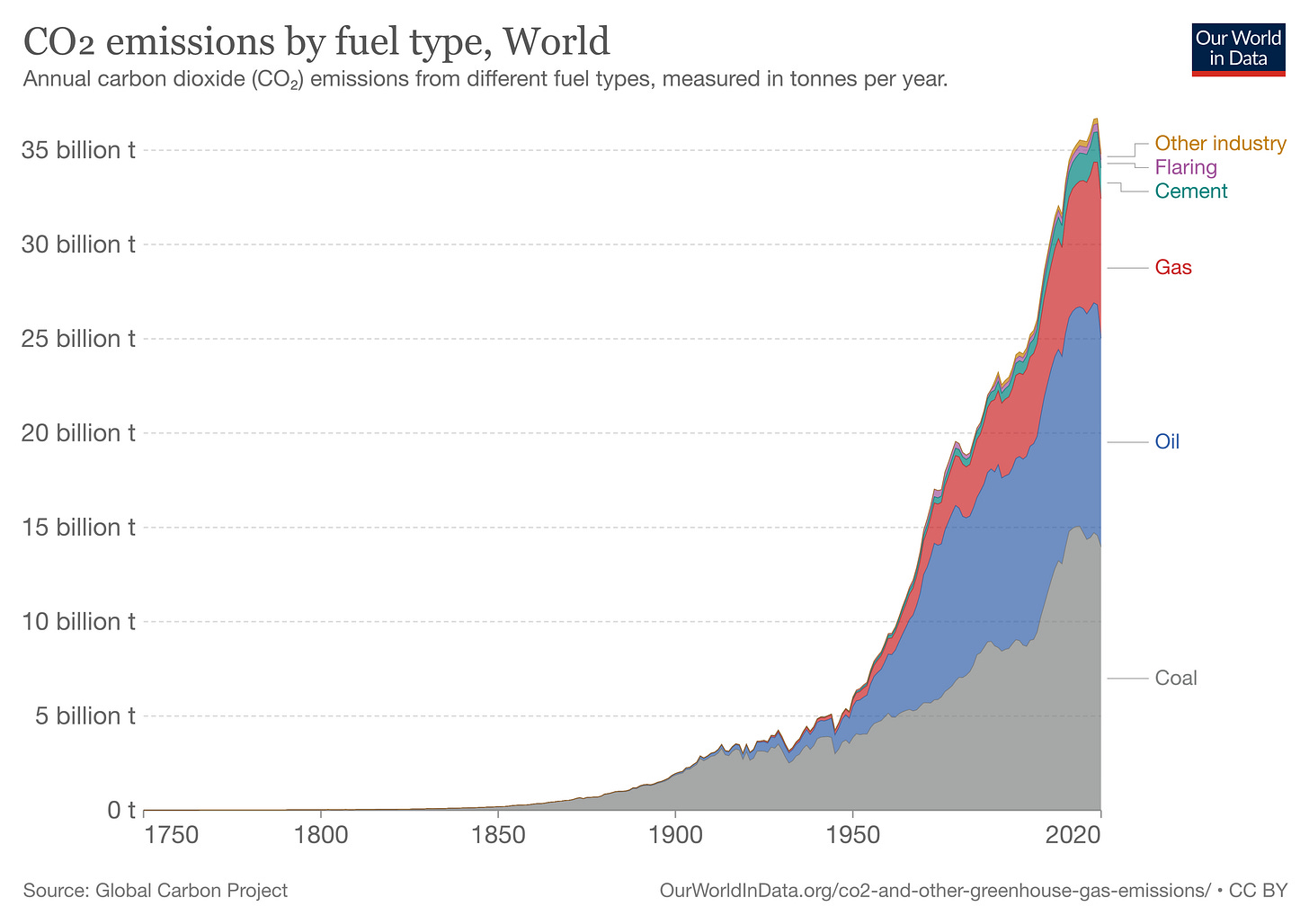

I am talking about concrete here.

It is responsible for 8% of greenhouse gas emissions.

And it’s used in every building.

Whether it’s our home, office, parking space, bridges or the majestic Burj Khalifa.

Concrete is a mix of sand and gravel, with a cement binder and water.

And the cement production process releases huge amounts of CO2.

50% of it comes from the chemical process and 40% from burning fuel.

Did you already know about cement and concrete?

For this week, I have 3 startups that are making the construction industry greener⬇️

Most polluting industry…Building and construction industry is responsible for ~40% of all the carbon emissions in the world. 1/4th of it comes from materials and construction processes. So to cut down these emissions, we need, well…better materials and improved processes. 🤷🏽

Get rid of the archaic processes… French startup Vestack builds modular buildings using biosourced material. It has developed a digital design tool that simplifies and reduces the design time of a project. It assembles a lot of housing components in its own production facility, which are then assembled quickly into a unit.

Faster construction, improved supply chain & reduced pollution.

Carbon footprint comes down by 3x- no need to pack and ship material to the construction site.

All this without an increase in the cost for real estate companies and landowners.

These modules come together to form a unit and different units are stacked to form a building-

There’s another problem…Apart from being one of the biggest polluters, the construction sector also struggles with the waste problem. 60% of the world’s waste comes from it. When old buildings are demolished, all the material ends up in a landfill, instead of being reused. The reuse rates are less than 1%. 😠

♻️ construction industry…Concular is bringing these materials back into circulation. Starting in 2020, they prevent vast quantities of materials like wood, plastic, windows and tiles which are removed from demolished buildings, from ending up in landfills. Instead, they list them on their portal from where the potential buyers can purchase them directly.

The Concular team takes the images of the items even before they are removed from the building and uploads them on the portal.

The buyers can place the order based on their requirements.

Once the items are removed, they are sent directly to the buyer- no additional transportation and storage.

Everyone’s happy…Manufacturers can also buy back the material from their old buildings, which brings down the cost of their new buildings. Demolition firms are happier as they don’t have to dispose of a ton of stuff. And watching the resources being reused, the planet is smiling too🌞

Widely used…When we think of construction, we think of steel and cement. And rightly so, they are the 2 most used construction materials in the industry. Their manufacturing and usage release huge amounts of greenhouse gases. Then there’s timber, which can be regrown but that doesn’t happen overnight.

Enter…Singapore-based Widuz aims to revolutionize the building and construction industry. It has developed an environmentally-friendly and sustainable alternative called BVL (Bamboo Veneer Lumber). It has the exceptional strength-to-weight ratio and durability of bamboo(comparable to steel and concrete) minus its disadvantages- decay and fast degradation.

Bamboo can be harvested within three to five years of planting as opposed to timber which takes decades.

It regrows without needing to be replanted and its large roots protect against soil erosion and landslides.

It also sequesters carbon when it grows and after harvest, making it potentially carbon-negative.

Applications…Widuz uses BVL to manufacture structural elements like beams, columns, trusses which are usually made of non-renewable materials like concrete, timber and steel. They also plan to use it for non-structural products like decorative panelling, flooring, door and window, frames, countertops, cladding and kitchen top.

🙋Trivia of the week

________ method of plant cultivation is widely considered more sustainable than regular farming for three reasons:

It uses around 90% less water

It yields more vegetables and herbs in a shorter time

Its carbon footprint is minimal as the greens are grown locally.

The name is derived from two Greek words meaning water and labour.

What method are we talking about?

📊Stat of the week

If you liked this edition, please do share it. That would mean a lot😊

Thanks and see you next week😄