We have a reuse before recycle system in our house

And this is how it works

Grocery items, Amazon parcels, food delivery- it’s hard to avoid plastic in all of them.

And even if we throw it in the recycling bin, the chances of it getting recycled are very slim.

So there’s an unsaid rule in our house- reuse before recycling.

We wash all the plastic and reuse it for as long as we can.

And this plastic has a dedicated space in the house.

It’s used to store food, personal care items, and electronics.

It’s used as a desk and bathroom organizer.

Every corner of the house has an empty food container now.

Not very aesthetic, but functional!

Do you reuse plastic at your home?

Would love to know more creative ways to reuse it.

This week, I wrote about 3 startups that are upcycling different types of waste and giving them a second life.

A sticky situation…Chewing gum is a universal activity that is mostly followed by throwing it on the ground- causing those unsightly blots. In the UK, it costs city councils 60 million pounds a year to remove chewing gum litter from the streets. Even if you throw it in the dustbin, it would end up in a landfill and would sit there for decades.

Second life…Gum consists of synthetic rubber. So UK-based Gumdrop recycles and processes chewing gum into a range of new compounds that can be used in the rubber and plastics industry. It partners up with cities, communities, and companies and gives them Gumdrop Bins- pink coloured bins designed for gum disposal. It then collects the gum waste, recycles and produces Gum-tec®- the raw material for the rubber and plastic industry.

Gum-tec® is used to manufacture boots, phone covers, and stationery products.

Even the Gumdrop Bins are made of Gum-tec®- closed-loop manufacturing.

They also have Gumdrop On-the-go, the portable mini version of Gumdrop Bins.

Gumshoe…One of their recent partnership was with marketing organization Iamsterdam and designer Explicit Wear. They used recycled gum that was scraped from the streets in Amsterdam to produce Gum-tec®. And that Gum-tec® was used to manufacture shoe soles. The sole also features a map of the city.

That’s a lie…Plastic hardly gets recycled. Most of it ends up in landfills or oceans and sits there for centuries. Every piece of plastic that you would have used in your life is still lying somewhere on the planet- it might have broken down and got ingested by a marine creature. Or it could be taking up space in some landfill- but it’s not gone.

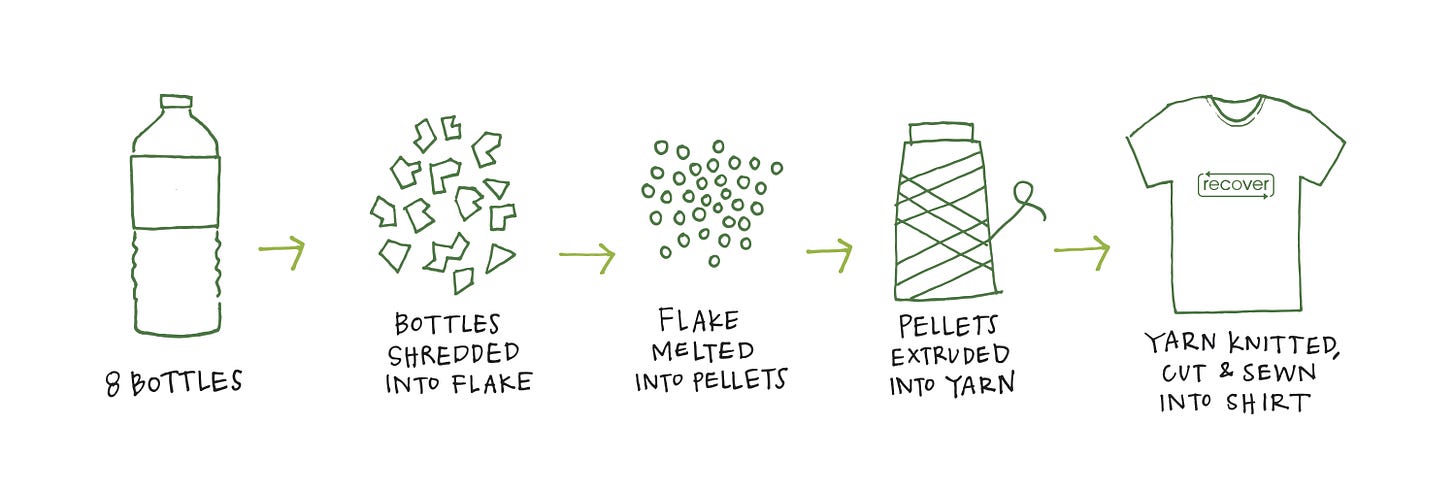

Clothes from plastic…A mission-driven sustainable apparel company, Recover prevents plastic from ending up in the environment by turning it into apparel. Based in North Carolina, US, they collect plastic and aluminum waste, sort them out, turn them into pellets, manufacture yarn and knit them into apparel.

This prevents plastic from polluting the environment.

The entire process is done within 250 miles radius of the source plastic- bringing down the transportation emission.

Customers can even send their old Recover clothes which are then upcycled into new products.

All in one place…To bring down their emissions, wastage and cost, they have built a vertically integrated factory in El Salvador, a country in Central America. Everything from spinning recycled fibres into yarn to sewing a finished garment is done in this factory.

It just took one visit…Sirohi is a little arcadian village in the northern state of Haryana in India. Gauri Malik first visited that village way back in 2012 and saw local women make charpai(a traditional woven bed used across South Asia) using chocolate wrappers. It stuck with her and 7 years later, in her own hometown in India, she started Sirohi- an artisan-led brand that believes in women empowerment and sustainability.

Breaking barriers…The brand works with women artisans in rural communities to manufacture products for the global conscious consumer. They make chairs, stools, benches & signature charpais from natural or up-cycled waste materials. In these rural communities, it is not customary for women to work outside the household. Providing them with employment, it’s breaking the social barriers and making them financially independent.

For their products, they use ropes made from waste from packaging units.

They also use cloth waste materials created during the manufacturing process.

For all of their products, they show a sustainability metric to the consumers.

Training and support…All of the women are trained by an in-house team, using support from designers in India and the UK. Teaching is often conducted through WhatsApp video calls and YouTube videos, to avoid the need for travel. These women are not only trained to design new products but are also taught financial literacy, ensuring that each craftsperson knows exactly how much their products sell for.

🙋Trivia of the week

This energy has been chugging along in the background for decades, never quite breaking out of its little niche, forever causing energy experts to say, “Oh, yeah, <energy>, what’s up with that?”

After many years of failure to launch, new companies and technologies have brought this energy out of its doldrums, to the point that it may finally be ready to scale up and become a major player in clean energy.

This also provides an opportunity for the struggling oil and gas industry to put its capital and skills to work on something that won’t degrade the planet.

Which energy are we talking about here?

Thanks for reading today’s edition. If you liked it, please consider sharing it with your network

See you next week👋

Geothermal energy 🌏!